Dongguan Magnetoelectronics Technology Co. Ltd..

Contact: Miss Zhang

Tel: 0769-22336260

Mailbox: 3468754465@qq.com

Website: www.magpresee.com

Address: Room 102,No.7 Xingye Road,Low Chung,Gaobu Town,Guangdong,Dongguan City,Guangdong province

With the advantages of rare earth resources and costs, China has vigorously developed the neodymium ferroboron permanent magnetic material industry, which has become the country with the largest production and sales of neodymium iron boron in the world. Data show that China's annual sales of rare earth permanent magnetic materials are about 100,000 tons. The global share reaches 80-90 %. In recent years, with the rapid development of the industry in the field of rare earth permanent magnetic materials, there have been nearly 10 enterprise groups producing and selling over 100 million yuan, as well as more than 10 top 100 enterprises in electronic components and more than 20 enterprises with export earnings exceeding US$ 1 million. Shows that the industry is moving into & amp; Quot; Fast Track &; Quot; And ...

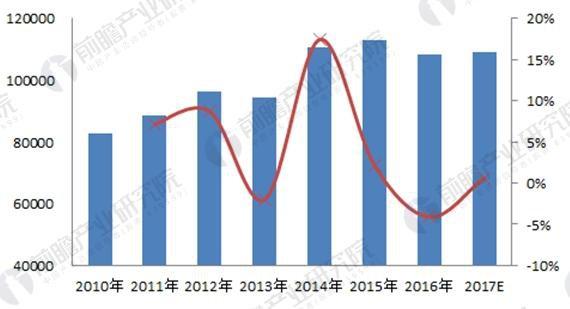

Production scale of rare earth permanent magnetic materials in China, 2010-2017(in tons, %)

At present, the application of rare earth permanent magnetic materials in magnetic resonance imagers, motors, audio, magnetic separators, electrometers, magnetometers, sensors and other devices has expanded, and has made great progress in the fields of high and new technologies, national defense, industry and agriculture, and household appliances. In recent years, new applications such as seismometers, permanent magnetic iron removal equipment, magnetic seepage drugs, electric vehicles, and automobiles have developed rapidly. At present, the application ratio of sintered neodymium iron boron in various fields in China is: electric acoustic sound accounted for 32 %, magnetizer accounted for 21 %, motor and sensor accounted for 31 %, magnetic coupling shaft and magnetic separator accounted for 9 %, sound coil motor and electric meter accounted for 5 %, others 2 %.

Application ratio of sintered neodymium iron boron materials in various fields in China(unit: %)

The production and application development of bonded neodymium iron boron permanent magnetic materials are relatively late, the application area is not extensive, and the amount of usage is small. It is mainly used for office automation equipment, electrical machinery, audio-visual equipment, instrumentation, small motors, and metering machinery. In recent years, the proportion of applications of bonded neodymium iron boron permanent magnetic materials in China is as follows: computers account for 62 %, electronics industry accounts for 7 %, office automation equipment accounts for 8 %, automobiles account for 7 %, appliances account for 7 %, and others account for 9 %.

Application ratio of neodymium iron boron permanent magnet materials in various fields in China(unit: %)

At present, the main product of rare earth permanent magnetic materials is neodymium iron boron, but from the current needs of technology development, neodymium iron boron also has certain limitations. In general, magnets fall into two categories: sintered magnets and bonded magnets. Neodymium iron boron sintered magnet is anisotropic and is a fully dense magnet, which is widely used. The neodymium iron boron bonded magnet is isotropic, and the deficiency of neodymium iron boron bonded magnet is constantly highlighted. First, its magnetic powder is isotropic, and the maximum magnetic energy product is only 16MGOe; Second, the forming process also has certain limitations: Ndfb is mainly used to make compressed bonded magnets, and its output accounts for only 3 % of the total bond magnet production. With the development trend of miniaturization of electrical appliances, the development of bonded magnets with high magnetic energy has become a new demand direction in the market.